Products

AHT products cover indoor heating, outdoor de-icing and snow-melting, based on our revolutionary and unique Amorphous Metal Ribbon Heating Technology.

Highly efficient heating at low cost, it is a totally safe, environmentally friendly system which is easily installed and requires no maintanance for both Indoor and Outdoor heating.

AHT’s technologically advanced underfloor electrical heating system provides a warm, comfortable, luxurious home environment.

AHT Snow-and-Ice Melting systems are based on our unique amorphous metal ribbon heating technology.

Advantages of AHT’s Amorphous Metal Ribbon Underfloor Heating for All-Around Warmth.

INDOOR

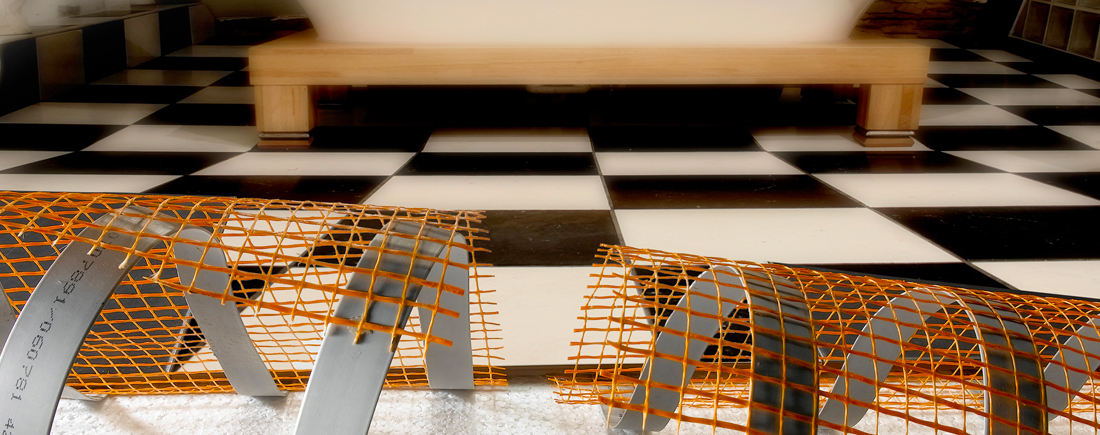

AHT’s technologically advanced underfloor electrical heating system provides a warm, comfortable, luxurious home environment. For use in every room such as the bathroom, kitchen, living room, utility room, basement, den, or bedroom, it can be installed under any flooring type such as tile, stone, wood, laminate or carpet according to our official installation manual. The AHT underfloor heating system gives a constant and exceptionally comfortable heat, with no blasts of hot air from noisy fans or blowers to stir up dirt and dust. The absence of unsightly radiators makes furniture placement easier and creates a safer home environment with no exposed hot surfaces.

The AHT Underfloor Heating system, based on a unique Amorphous Metal Ribbon heating technology, has significant advantages over any other type of underfloor heating system:

- Its suitable and can be installed under all types of floor coverings

- It reaches working temperatures faster than other systems

- It generates more consistent heat

- It is less costly and more economical to operate

- It has a low profile and superior flexibility

- It is extremely simple and easy to install

- It is perfectly safe from electrical shock hazards and electromagnetic radiation

- It is reliable and durable.

AHT heating mats are designed and manufactured to the highest safety standards and meet class II appliance requirements; are constructed with double insulation and have successfully passed the applicable tests of IEC safety standards: IEC En 60335-1:2012;A11 (Household and similar electrical appliances – safety, general requirements) and IEC En 60335-2-96:2002;A1:A2 (particular requirements for flexible sheet heating elements for room heating), as well as IEC En 62233:2008 (Electromagenetic fields of household apparatus with regard to human exposure).

The AHT heating mats are certified and listed by Underwriters Laboratories (UL) based on UL 1693 (Electric Radiant Heating) standard, Certificate Number E349312 as well as Nemko, Cerificate Number P15220551 and therefore proudly carry the CE, the Nemko N and CB as well as the UL marks.

WHAT IS UNDERFLOOR HEATING?

Underfloor heating, an idea first used by the ancient Romans, is once again becoming the most popular form of heating in the United States, the UK and throughout Europe from East to West. Because of its superior comfort and efficiency, people are discovering that a radiant underfloor heating system has more advantages than they believed possible.

Underfloor heating gives a constant and extremely comfortable heat, with no blasts of hot air from noisy fans or blowers to stir up dirt and dust. The absence of unsightly radiators makes furniture placement easier and creates a safer home environment with no exposed hot surfaces.

Underfloor heating radiates comfortable, constant warmth with healthy, clean, quiet and safe heat to the occupants and surfaces of the room.

FEELING WARM ALL OVER BEGINS WITH THE FEET

It’s true. When your feet are warm, you feel warmer and more comfortable all over. Because the AHT heating system heats rooms through the floors, the air temperature is always highest at floor level and decreases steadily toward the ceiling. That’s comfort!

The moisture content of the room is more stable and healthy. Unlike forced air heat, radiant heat is less likely to dry out your nasal passages, less likely to dry out the skin, and less likely to cause damage to furniture.

Because the air is not dehumidified, it feels several degrees warmer than it really is. And for every single degree of lower temperature, you save energy and money.

EVEN THE ELECTRICITY BILLS WILL LEAVE YOU FEELING COMFORTABLE

Comfort alone is a good enough reason to invest in an AHT underfloor heating system, but there are other good reasons…like cost-savings and energy efficiency.

With an AHT underfloor heating system, people often discover that they are comfortable at temperatures lower than those provided by conventional systems…and lower temperature settings mean lower electricity costs.

With AHT underfloor heating systems, savings begin with the purchase of the system. Not only do our systems cost less to purchase and install than other radiant underfloor systems, they usually cost less to operate.

Discover the comfort, feel the warmth, and enjoy the efficiency of radiant underfloor heating.

Ask your nearest AHT distributor for a quotation for your next building or renovation project. You’ll be surprised how economical radiant underfloor heating can be.

OUTDOOR

AHT Snow-and-Ice Melting systems are based on our unique amorphous metal ribbon heating technology. They have significant advantages over other types of hydronic or electrical cable- based Snow Melting and Ice Prevention systems.

AHT currently supplies three families of products:

- Underground – U Outdoor heating ribbons

- Roof and Gutter – G Outdoor heating ribbons

- Road – R Outdoor heating ribbons

Among the benefits of the AHT Snow Melting and Ice Prevention systems are:

- Wider contact area with the cold ground or ice

- Reaches the working temperature faster than other systems

- Energy saving

- Generates more even heat

- Less costly

- Extremely simple and easy to install

- Reliable and durable.

Intended for use under concrete, asphalt, paving stones, gravel and natural or artificial grass to heat sportsfield of all types such as football, rugby, tennis, golf etc. as well as for agricultural applications. The heating element can be driven by various power voltage sources, AC or DC: 110-120, 208, 220-240, 400 and 600 Volts, as long as the current limit is met. Low voltage (below 50 volts) usage is also possible. The upper limit working temperature of the heating element is 70C.

All AHT Outdoor heating ribbons are based on a unique design of fully grounded heat-tracing cable made of amorphous metallic ribbon enclosed in a mechanically robust flexible enclosure. The element is designed to meet IEEE 515.1 standards for underground and outdoor exposed applications and are fully certified and listed by INTERTEK and proudly carry the ETL mark.

AHT SNOW MELTING AND ICE PREVENTION

AHT’s Snow-and-Ice Melting system is ideal for external concrete, asphalt, paving stones, gravel and lawns/turf (sports fields etc). Based on our unique Amorphous Metal Ribbon Technology they have significant advantages over any other type of hydronic or electrical cable-based Snow Melting and Ice Prevention systems.

BENEFITS

Benefits are as follows:

- Larger contact area with the cold ground or iced surface

- Reaches the working temperature faster than other systems

- Energy saving

- Less costly

- Generates more even heat

- Extremely simple and easy to install

- Perfectly safe from electrical shock hazards and electromagnetic radiation

- Reliable and durable

AHT HEATING ELEMENTS

AHT currently supplies two product families:

- Outdoor underground heating ribbons or mats normally at 250 – 500 Watts/m2

- Pipes and Gutters Freeze Protection/Heat Tracing ribbon

Both families are based on a unique design of fully grounded heat-tracing cable made of amorphous metallic ribbon enclosed in a mechanically robust flexible enclosure. The element is designed to meet IEEE 515.1 standard for underground and outdoor exposed applications.

HEATING ELEMENT PERFORMANCE

The heating element is of a fixed wattage. By using different widths of amorphous ribbons and different length of the element itself, one can achieve the required output power per linear meter/foot. Typically the high-end limit for the heating element power is 62 watts per meter. This limit corresponds to more than 5 amps on a single circuit. The heating element can be driven by various power voltage sources, AC or DC: 110-120, 208, 220-240, 400 and 600 Volts, as long as the current limit is met. Low voltage (below 50 volts) usage is also possible. The upper limit working temperature of the heating element is 70°C.

GEOMETRIC DIMENSIONS

The heating mats are designed to cover a nominal 20% of the heated area, but the normal area-covering density ranges from 15% to 30%. Other values are also possible.

ELECTRICAL MEASURES

The normal input power of each heating mat is 250 – 500 watts/m2. as specified on each heating mat label. Higher input can easily be achieved by reducing the spacing between parallel heating elements.

ADVANTAGES & SAFETY

Advantages of AHT’s Amorphous Metal Ribbon Underfloor Heating for All-Around Warmth, ideal for:

- Bathroom

- Kitchen

- Den

- Basements

- Lounge

- Bedrooms

The AHT Underfloor Heating system, based on a unique Amorphous Metal Ribbon heating technology, has significant advantages over any other type of underfloor heating system:

- It fits into floors directly under all types of surfaces

- It reaches working temperatures faster than other systems

- It generates more consistent heat

- It is less costly and more economical to operate

- It has a low profile and superior flexibility

- It is extremely simple and easy to install

- It is perfectly safe from electrical shock hazards and electromagnetic radiation

- It is reliable and durable

IT CAN BE INSTALLED INTO FLOORS DIRECTLY UNDER ALL TYPES OF SURFACES

AHT heating mats are constructed from wide metallic ribbons that cover at least 25% of the floor area (compared to only 1% to 2% with heating wires). This large heat transfer area allows the heating element to operate at very low temperatures of about 30 degrees (compared to the typical temperature range of more than 60 degrees at the core of a common heating wire), and still generate the required heat to the surrounding area.

The low working temperature allows installation into floors directly under different types such as ceramic tile, timber, parquet etc.

IT REACHES WORKING TEMPERATURES FASTER THAN OTHER SYSTEMS

The large heat transfer area of the heating ribbons and the short distance between the heating element and the floor covering ensure that the floor temperature reaches the desired level faster than wire systems buried deeper in the floor.

AHT heating mats are constructed from wide metallic ribbons that cover at least 25% of the floor area (compared to only 1% to 2% with heating wires). This large heat transfer area allows the heating element to operate at very low temperatures of about 30 degrees (compared to the typical temperature range of more than 60 degrees at the core of a common heating wire), and still generate the required heat to the surrounding area.

The low working temperature allows direct installation of ceramic tile, timber, parquet or carpet above the heating mats with no danger of damaging the color, texture or coating of these delicate floor coverings.

IT GENERATES MORE CONSISTENT HEAT

AHT heating mats are constructed from wide metallic ribbons that cover at least 25% of the floor area (compared to only 1% to 2% with heating wires). This high coverage creates extremely consistent heating over the top of the floor covering.

IT IS LESS COSTLY AND MORE ECONOMICAL TO OPERATE

Because AHT heating mats reach the desired working temperature faster, activating the system to reach a desired temperature can be started later than a comparable wire-based system, resulting in lower operating costs.

The heating ribbons transfer all the electrical energy into heat and as the ribbon thickness is minimal (1/1000th inch), heat is not stored in the heating element itself; all heat is distributed into the surrounding area -resulting in superior economical operating costs.

IT HAS A LOW PROFILE AND SUPERIOR FLEXIBILITY

The heating ribbon is only 1/1000th inch thick. The total mat thickness, including the double insulation, is less than 1/10th inch therefore perfectly suited not only for installation in new buildings, but also for renovation, refurbishment and retrofitting projects.

State-of-the-art technology mean virtually no change to the elevation of the floor during renovations.

IT IS EXTREMELY SIMPLE AND EASY TO INSTALL

Just lay the heating mats on the sub-floor, connect the electrical cables and you are ready to cover the floor with any type of covering.

IT IS PERFECTLY SAFE FROM ELECTRICAL SHOCK HAZARDS AND ELECTROMAGNETIC RADIATION

IT IS RELIABLE AND DURABLE

The AHT amorphous metal underfloor heating system will last for many, many years, with minimal maintenance, giving trouble-free, comfortable and safe All-Around Warmth ,way into the future, at low cost.

AHT heating mats

are designed and manufactured to the highest safety standards.

The heating mats meet class 2 appliance requirements; are constructed with double insulation and have successfully passed the applicable tests of IEC safety standards: IEC 60335-1 (Household and similar electrical appliances – safety, general requirements) and IEC 60335-2-96 (particular requirements for flexible sheet heating elements for room heating).

The heating mats are also certified and listed by Underwriters Laboratories (UL) based on UL 1693 (Electric Radiant Heating) standard, file E349312.

As such the AHT products proudly carry the CE mark, have the CB mark, the Nemko N mark and the UL mark. Furthermore they have been tested, approved and certified by a number of national safety organizations such as the SAA – Australia, ISI – Israel, GOST – Russian Federation, PSE – Japan.

AHT outdoor heating ribbons

are designed and manufactured to withstand harsh external conditions and meet the highest international safety standards.

The outdoor heating ribbons are based on a unique design of fully gounded heat-tracing amorphous metal ribbon heating element enclosed in a mechanically strong but flexible enclosure. They meet the IEEE 515.1 standard for undergound and outdoor exposed applications.

As such the AHT outdoor heating ribbons have been globally approved by Intertek and proudly carry the ETL mark.

AHT products have been tested and have been found to have negligible electromagnetic radiation, far below the minimum requirements of the applicable standards. As such they have been approved by Nemko and have the appropriate certification.

All AHT products when installed according to the installation instructions outlined in the appropriate AHT installation manual, are perfectly safe and achieve the highest performance levels.